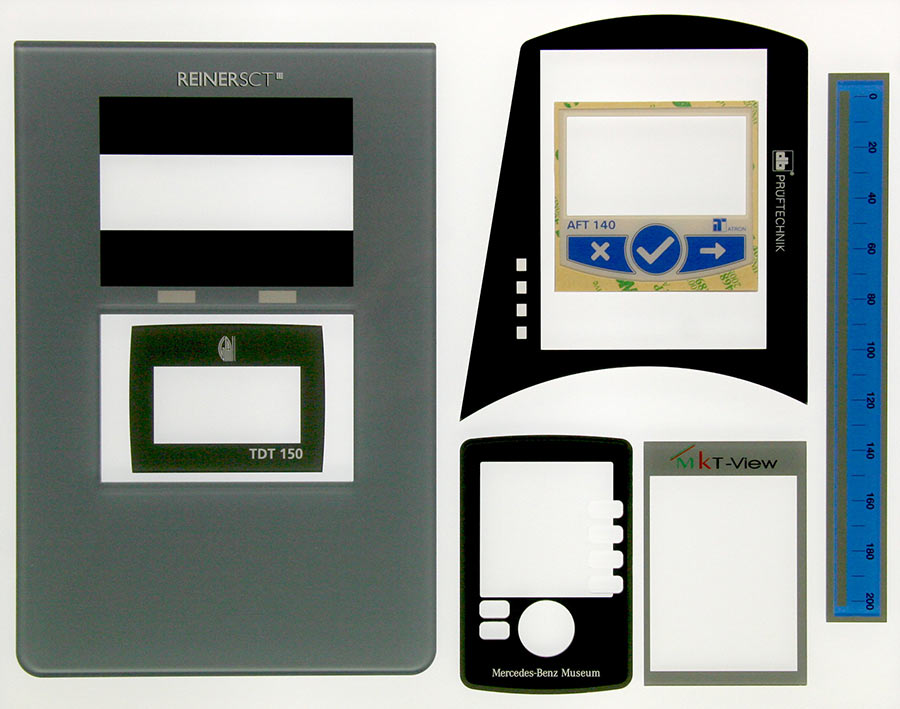

Display Windows

Find the perfect display filter for a perfect image on your HMI

Display windows or cover glasses should not only provide protection against mechanical damage, UV radiation, contamination or aggressive substances. Depending on the requirements of the device, the legibility and contrast of the display must be increased, reflections must be avoided, and disturbing background brightness must be reduced by suitable colour selection of the filter.

If EMC is required, the respective enclosure opening must also be shielded in front of the display.

For all these requirements, ttv supplies ready-to-install solutions in plastic (precision cast acrylic or polycarbonate) or glass.

For your company-specific design, we supply display windows with colour print according to your specifications (your logo, lettering, colour design or even "secret until lit").

Your benefits

Various surface refinements (anti-reflective coating, hard coating and many more)

Extensive material range available ex stock

No minimum order quantity

Custom manufacturing including print

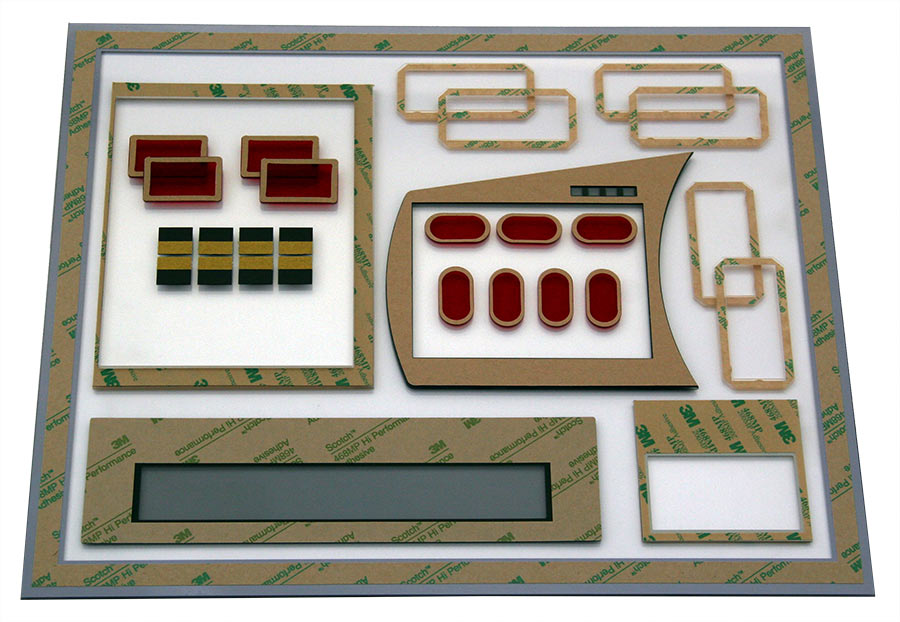

Protection films

Kleberausrüstung

For fast and clean mounting of the display windows: customized adhesive frames or passepartouts made of various double adhesive films (e.g. TTV0403, TTV0404 for low-energy surfaces, 3M-MP200). The adhesive frames are already applied to one side of the display filter. For the final assembly of the device, just remove the protective film on the back and fit the cover glass into the housing.

Silver lacquer (Busbar)

Display windows with EMC requirements can be provided with conductive lacquer on the cut edges for contacting with the device cabinet.

Biegen

Even for unusual designs and constructions with non-planar surfaces, ttv produces cover glasses made of cast acrylic glass. Sheet material (in limited cases even coated material) is bent to the required radius.

Max. dimension: 770 x 500 mm

Applications

Front panel for retro car radio

2-part cover glass for high-end radio front panel with maximum anti-reflection coating and complex, finely detailed screen printing, self-adhesive

Cover glass with scratch-resistant matt anti-reflection coating for touch display

Polycarbonate filter with anti-reflective and scratch-resistant surface

Screen printing and adhesive equipment for touch display in premium fully automatic coffee machines for professional use

LCD display cover

in two versions for use in floor conveyor vehicles

- a) high-end design with maximum anti-reflection coating, larger viewing area, with screen printing and self-adhesive gasket

- b) Simpler version with scratch-resistant, matt anti-reflection coating, tinted blue with screen printing and self-adhesive gasket

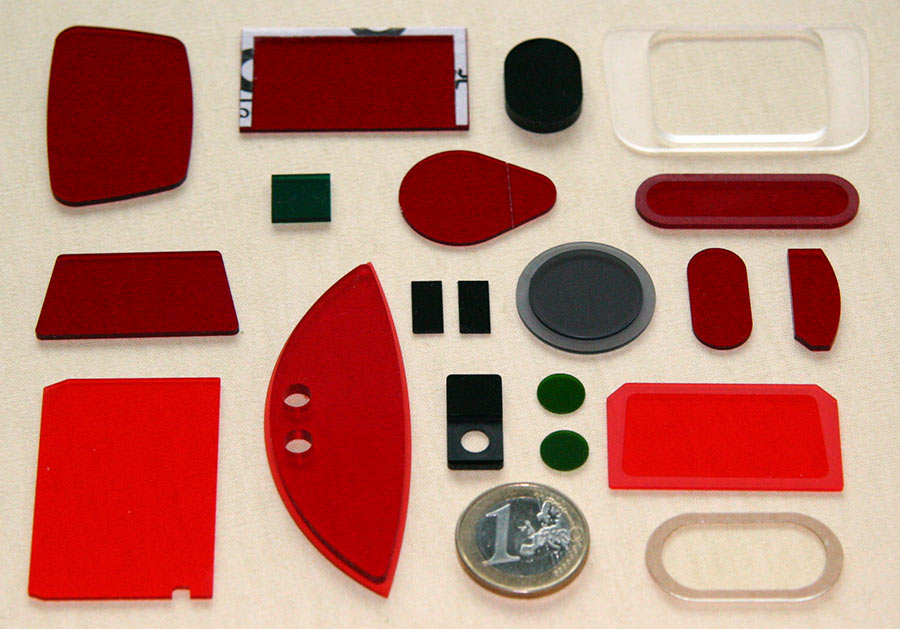

Sensor and Scanner windows for every imaginable project

ttv manufactures a wide range of customized optical filters for laser scanners, sensors and light grids

Ready to get specific?

Stephan Zuber

executive director

Frequently asked questions from customers

Do you offer display windows for harsh application environments?

Yes. We offer material and hard coating in highest optical quality, but also break and impact resistant, vandal proof material like PC.

Do the display screens offer UV protection?

Our acrylic is always manufactured with UV blocker. This makes it UV-stable and provides UV protection and weather resistance at the same time.

How can we reduce reflections on our HMI (Human Machine Interface)?

Basically, there are 2 types of anti-reflection coating:

- diffuse matt anti-reflection coating (non-glare) on acrylic glass and PC, which can be combined with hard coating or

- optical grade anti-reflection coating for highest transmission and lowest reflection, which can be combined with diffuse matt anti-reflection coating on acrylic glass.Can optical filters be supplied with printing?

We offer both screen prin and digital print on acrylic and Polycarbonate; for acrylic even on hard coated and anti-reflective surfaces.

How can I install or attach the display window in my device?

There are the following possibilities:

-liquid adhesives (e.g. silicone) on flange milling

-adhesive frames made of common double-sided adhesive tapes, e.g. from 3M

-drill holes (with countersink) for screwed connection

-ultrasonic welding (for acrylic without hard coating)Do you offer curved display panels?

Display panels with curvature are possible, in large radii also for acrylic with hard coating and anti-reflection coating.