ANTIFLEX®-AR-PC/ITO

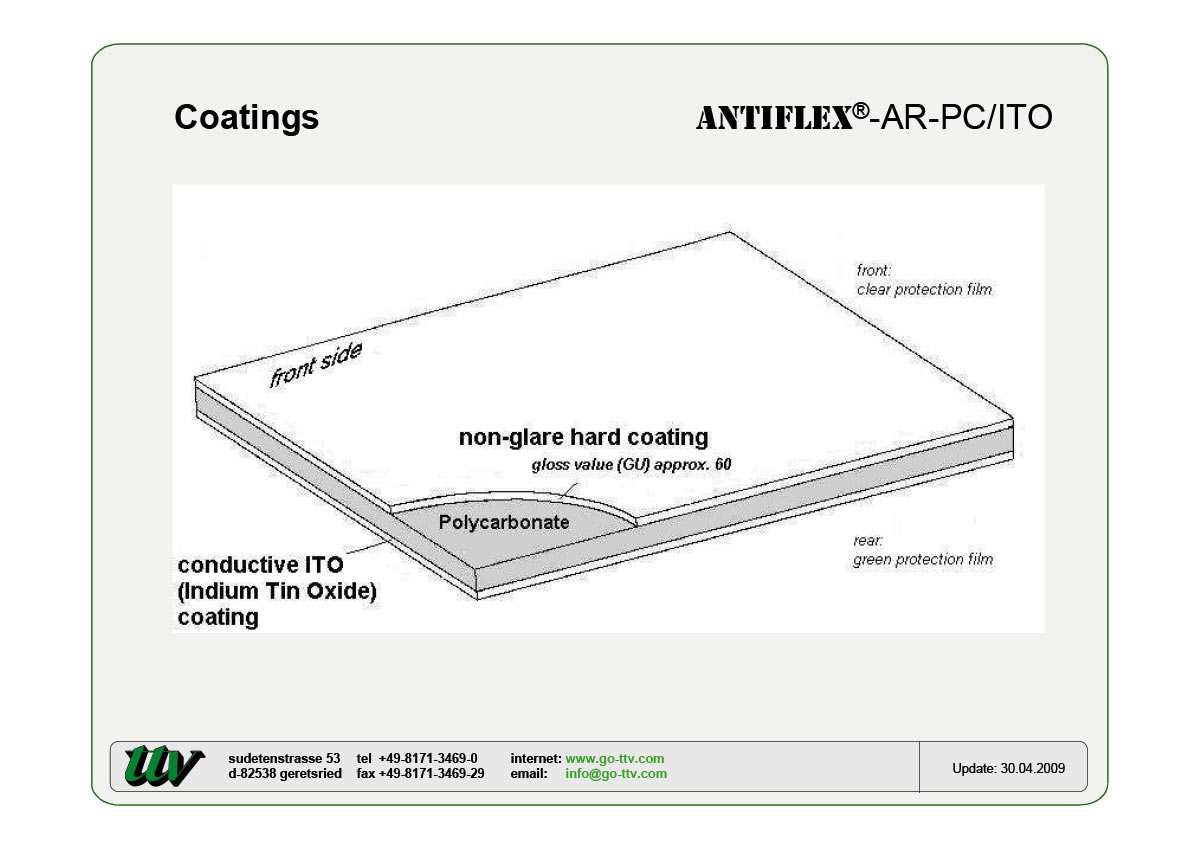

POLYCARBONATE with one-side non-glare coating and considerably increased scratch and chemical resistance – surface hardness approx. 5 H (pencil hardness) as on ANTIFLEX®-AR-PC, but with additional rear side ITO (Indium Tin Oxide) coating of app. 30 Ω/□ for display shielding

The ITO coating is accessible on the rear surface for ease of contacting. Silver lacquer – busbar – is not necessarily needed. Custom sheet sizes, thicknesses, and tints can be supplied upon request.

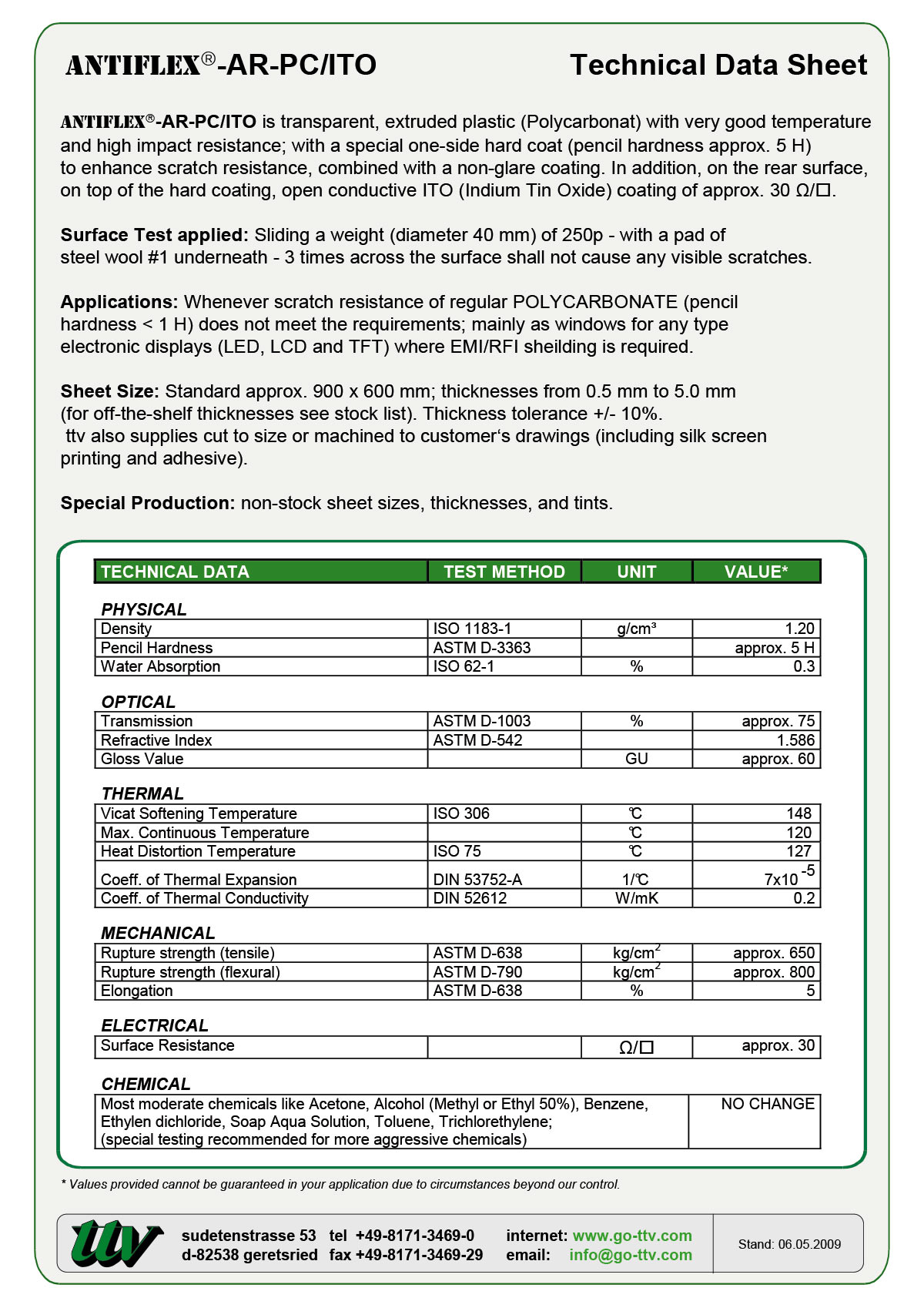

ANTIFLEX®-AR-PC/ITO is transparent, extruded plastic (Polycarbonat) with very good temperature and high impact resistance; with a special one-side hard coat (pencil hardness approx. 5 H) to enhance scratch resistance, combined with a non-glare coating. In addition, on the rear surface, on top of the hard coating, open conductive ITO (Indium Tin Oxide) coating of approx. 30 Ω/□.

Surface Test applied: Sliding a weight (diameter 40 mm) of 250p - with a pad of steel wool #1 underneath - 3 times across the surface shall not cause any visible scratches.

Applications: Whenever scratch resistance of regular POLYCARBONATE (pencil hardness < 1 H) does not meet the requirements; mainly as windows for any type electronic displays (LED, LCD and TFT) where EMI/RFI sheilding is required.

Sheet size: Standard approx. 900 x 600 mm; thicknesses from 0.5 mm to 5.0 mm (for off-the-shelf thicknesses see stock list). Thickness tolerance +/- 10%.

ttv also supplies cut to size or machined to customer‘s drawings (including silk screen printing and adhesive).

Special Production: non-stock sheet sizes, thicknesses, and tints.